English

T: +86-15817577177

E: Aimee@Topfive-Cable.Com

E: Aimee@Topfive-Cable.Com

No.1 Industrial Park, Tang Lian Road, Tangxia Town, Dongguan City, China.

Views: 211 Author: Site Editor Publish Time: 2024-03-06 Origin: Site

The car wiring harness is the carrier that connects the various components of the car circuit. Some people have made an analogy before. The car wiring harness is a blood vessel, the car engine is the heart, the heart beats due to the blood vessel, and the engine runs due to the wiring harness. It can be seen that the car wiring harness is related to the car circuit The importance of normal stability. Therefore, it is very necessary to understand the common knowledge of products and processes of car wiring harness.

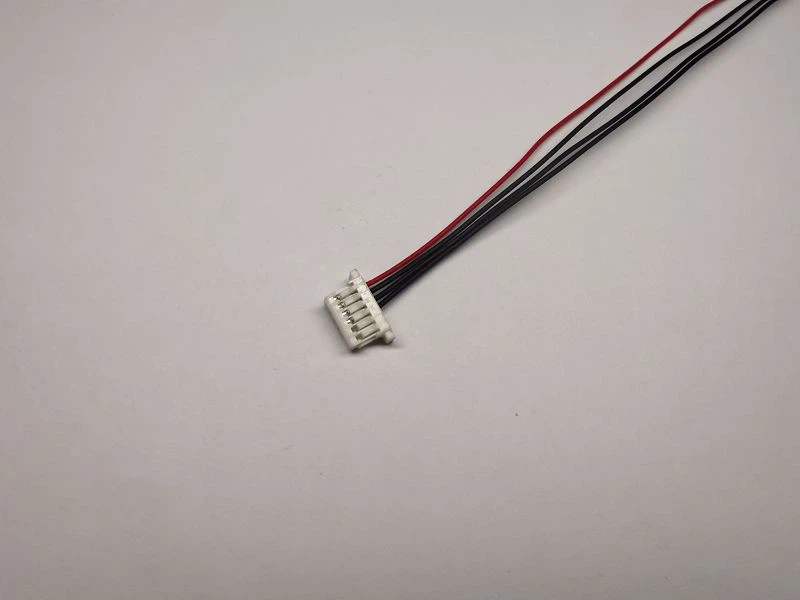

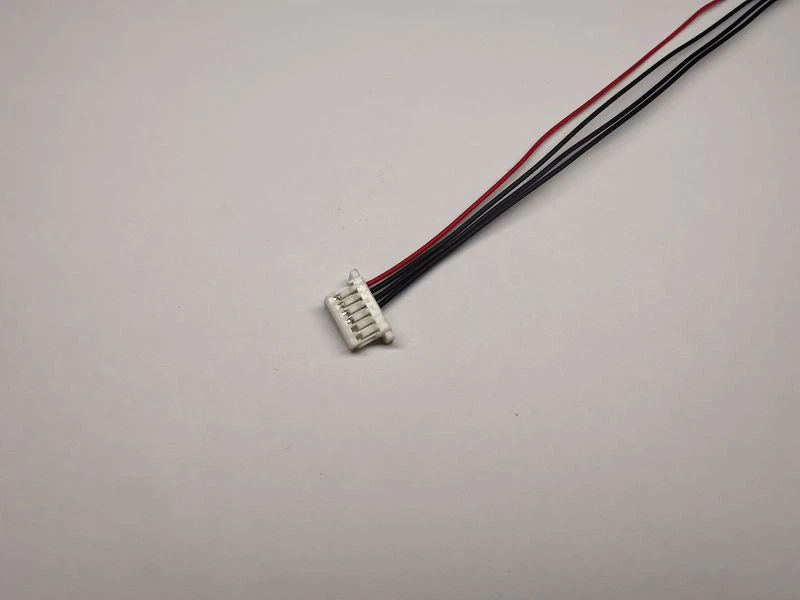

The wire harness refers to the contact parts (connector) made of copper material that are crimped with the wire and cable, and then the outer surface is molded with an insulator or an additional metal shell, and the assembly of the connected circuit is bundled with the wire harness. In short, it is the electric wire that connects the car's electrical appliances. The operating conditions and parameters of the car are reflected on the on-board computer through the wire harness. On the other hand, the electronic technology content of the car wiring harness has become an important target for commenting on the function of the car.

Automotive wiring harness classification Car wiring harness can be divided into main wiring harness and small wiring harness. The main wiring harness includes the engine wiring harness, center wiring box wiring harness, instrument panel wiring harness, cabin wiring harness, etc.; and the small wiring harness includes the door wiring harness, battery wiring harness, ABS brake wiring harness, etc. In addition, according to the voltage difference, the car wiring harness can be divided into high-voltage wiring harness and low-voltage wiring harness. The biggest feature of the car's high-voltage line is high voltage and small current, and high insulation function requirements, so the insulation layer is often thick and the core wire is relatively thin.

The production process of automobile wiring harness The production process of car wiring harness mainly includes opening, crimping, pre-assembly, final assembly, etc. The primary data of the wiring harness is heat shrinkable data, which is an important insulation material in the car wiring harness. The proportion of domestic heat-shrink materials used in car manufacturing is still very low, only about 20%. It is worth mentioning that 80% of the world's shopping malls are occupied by American Raychem and Japanese Sumitomo.

The development trend of automobile wiring harnesses With the development of electronic cars, the economy, comfort, reliability, etc. will become more and more prominent. Domestic car wiring harness malls will gradually be transformed from low-cost strategic malls to cost-effective malls with higher technological content. Car wiring harnesses are also developing in the direction of high pressure, light weight, and standardization.

BNC connector have a two-stud bayonet locking design, and has same interface with TNC connector. BNC connector supports with a large variety of coaxial cables like RG58, RG174, RG316, RG59.50 ohm BNC connector was commonly used on 10base2 thin Ethernet networks, and now is used in radio and telecomm

First, the electrical layout engineer will first provide the functions, electrical loads and related special requirements of the vehicle's electrical system. The state of the electrical device, the installation position, and the form of the harness connected to the electrical device.Second, accordin

Automotive wiring harness is the main body of automotive circuit network. Without a wiring harness, there is no car circuit. With the improvement of people's safety, comfort, economy and emission requirements, more and more electrical appliances and functions are on the car. Therefore, the wiring ha

With the continuous improvement of safety, comfort and environmental protection requirements of modern cars, the number of circuits and power consumption on the car have increased significantly, so how to arrange a large number of wiring harnesses in a limited car space more effectively and more rea

Waterproof joints have very strict standards and quality limits in use, so you must be very careful when purchasing to ensure safety and reliability. Waterproof joints are specially designed and applied to meet the requirements of harsh environmental conditions. The main application areas are indust

1) The glass sintered and sealed electric female device should avoid being struck or dropped strongly to avoid damage to the internal structure and affect the sealing performance.2) When the waterproof connector is in a separated state, it should be separately installed with protective pads to take

The use of industrial connectors is very common. For example, machinery and equipment special tools elevator car, household water heater, and its children's toys artificial intelligence technology and other commodities. Not only is it a cable, but in too many engineering equipment, there are often s

There are four basic structural components of the LED waterproof connector: 1. Contacts; 2. Insulator; 3. Shell; 4. Accessories.Contact: The contact is the core component of the connector, which is equivalent to the human heart. The connector relies on the contact to complete the connection between

Topfve cable was established in 2010 years.Our products are widely used in electrical products, industrial display screen, Medical display, UAV unmanned aerial vehicle and so on.