English

T: +86-15817577177

E: Aimee@Topfive-Cable.Com

E: Aimee@Topfive-Cable.Com

No.1 Industrial Park, Tang Lian Road, Tangxia Town, Dongguan City, China.

Views: 213 Author: Site Editor Publish Time: 2024-03-06 Origin: Site

In modern cars, the electronic control system is closely related to the wiring harness. Someone once used a vivid analogy: the microcomputer is equivalent to the human brain, the sensor is equivalent to the sensory organ, and the executive element is equivalent to the motion device tube, so the wiring harness is the nerve and blood vessel.

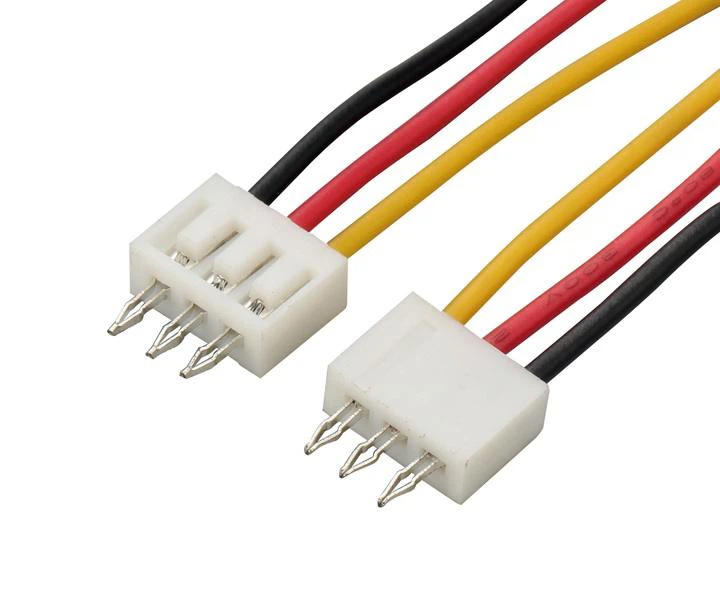

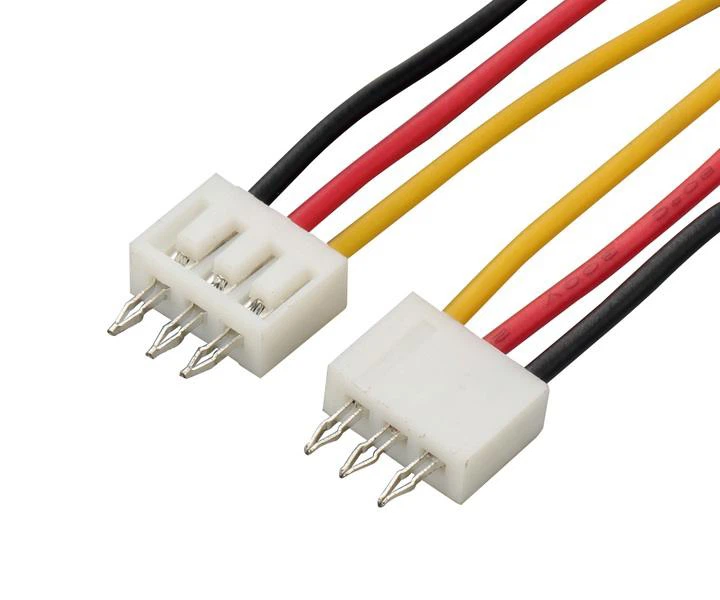

Automotive wiring harnesses are divided into functions, there are two types of power lines that carry power to drive the actuators (actuators) and signal lines that transmit sensor input commands. Power lines are thick wires that carry large currents, while signal lines are thin wires that do not carry electricity (optical fiber communication).

The cross-sectional area of wires used in motors and actuators is 0.85 and 1.25mm2, while the cross-sectional areas of wires used in power circuits are 2, 3, and 5mm2; while special circuits (starters, alternators, engine ground wires, etc.) have 8, 10, 15, 20mm2 different specifications. In addition to considering the electrical performance, the selection of wires is also restricted by the physical performance of the vehicle. For example, the frequently opened/closed door of a taxi and the wires that cross the body should be made of wires with good flexibility. In recent years, electromagnetic shielding wires used in weak signal circuits have also been increasing.

With the increase of automobile functions and the widespread application of electronic control technology, the number of circuits and power consumption on automobiles has increased significantly, and the wiring harness has become thicker and heavier. How to make a large number of wiring harnesses more effective and reasonable in the limited car space Arrangement to enable automobile wiring harnesses to exert greater functions has become a problem facing the automobile manufacturing industry.

BNC connector have a two-stud bayonet locking design, and has same interface with TNC connector. BNC connector supports with a large variety of coaxial cables like RG58, RG174, RG316, RG59.50 ohm BNC connector was commonly used on 10base2 thin Ethernet networks, and now is used in radio and telecomm

First, the electrical layout engineer will first provide the functions, electrical loads and related special requirements of the vehicle's electrical system. The state of the electrical device, the installation position, and the form of the harness connected to the electrical device.Second, accordin

Automotive wiring harness is the main body of automotive circuit network. Without a wiring harness, there is no car circuit. With the improvement of people's safety, comfort, economy and emission requirements, more and more electrical appliances and functions are on the car. Therefore, the wiring ha

With the continuous improvement of safety, comfort and environmental protection requirements of modern cars, the number of circuits and power consumption on the car have increased significantly, so how to arrange a large number of wiring harnesses in a limited car space more effectively and more rea

Waterproof joints have very strict standards and quality limits in use, so you must be very careful when purchasing to ensure safety and reliability. Waterproof joints are specially designed and applied to meet the requirements of harsh environmental conditions. The main application areas are indust

1) The glass sintered and sealed electric female device should avoid being struck or dropped strongly to avoid damage to the internal structure and affect the sealing performance.2) When the waterproof connector is in a separated state, it should be separately installed with protective pads to take

The use of industrial connectors is very common. For example, machinery and equipment special tools elevator car, household water heater, and its children's toys artificial intelligence technology and other commodities. Not only is it a cable, but in too many engineering equipment, there are often s

There are four basic structural components of the LED waterproof connector: 1. Contacts; 2. Insulator; 3. Shell; 4. Accessories.Contact: The contact is the core component of the connector, which is equivalent to the human heart. The connector relies on the contact to complete the connection between

Topfve cable was established in 2010 years.Our products are widely used in electrical products, industrial display screen, Medical display, UAV unmanned aerial vehicle and so on.